The sensor technology specialist elobau in Leutkirch is known for its sustainable solutions and was therefore keen extend its production hall at one of its factories with a “green” construction. For this striking building with a saw-tooth roof and a wood shingle facade, the architects combined BauBuche and glulam made from locally felled spruce to construct a supporting system that impresses by its simplicity.

elobau GmbH, Leutkirch, DE

July 2020

F64 Architekten, Kempten, DE

Helber + Ruff Ludwigsburg, DE

Jarde Holzbau, F64 Architekten

Pollmeier, D-99831 Amt Creuzburg

Rainer Retzlaff, Helber+Ruff

elobau is a manufacturer of contactless sensor solutions, technology for filling level measurement and control devices for machinery and industrial plants. As a foundation company, elobau has for many years been committed to sustainability, with regard to both its products and premises. The extension of its factory II in Leutkirch im Allgäu was completed in summer 2020. It is a timber hybrid construction designed by Büro F64 as a plus-energy building.

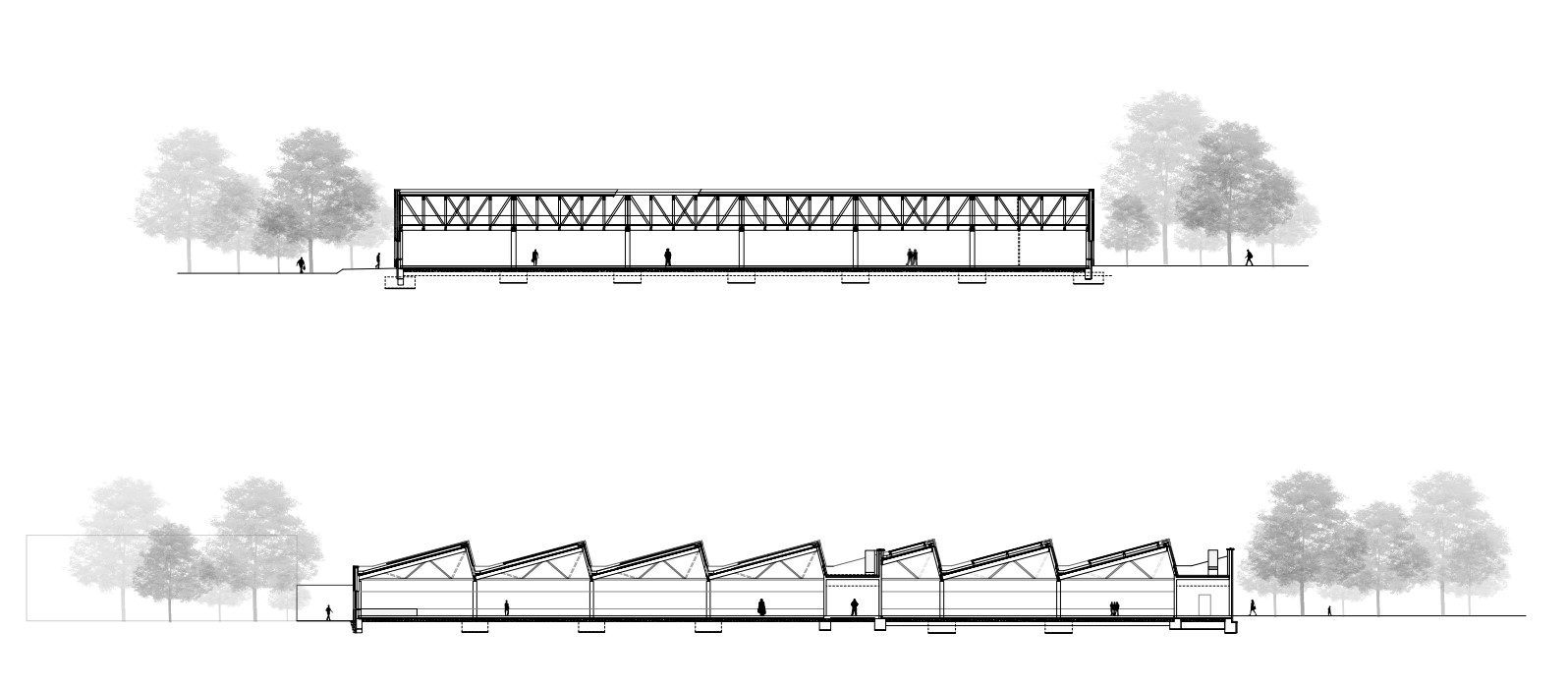

A dominant feature of the extension are the shed roof elements with rafters and lattice girders. For this construction, the architects combined BauBuche made from beech with spruce glulam. The exposed roof supporting structure creates an airy indoor ambience with attractive workplace and ample headroom.

The firm commitment of the proprietor to follow its “elobau-goes-green” mission for this industrial premises has won elobau two prestigious awards, namely the HolzbauPlus Award in 2020 and the German Environment & Building Award in 2021.

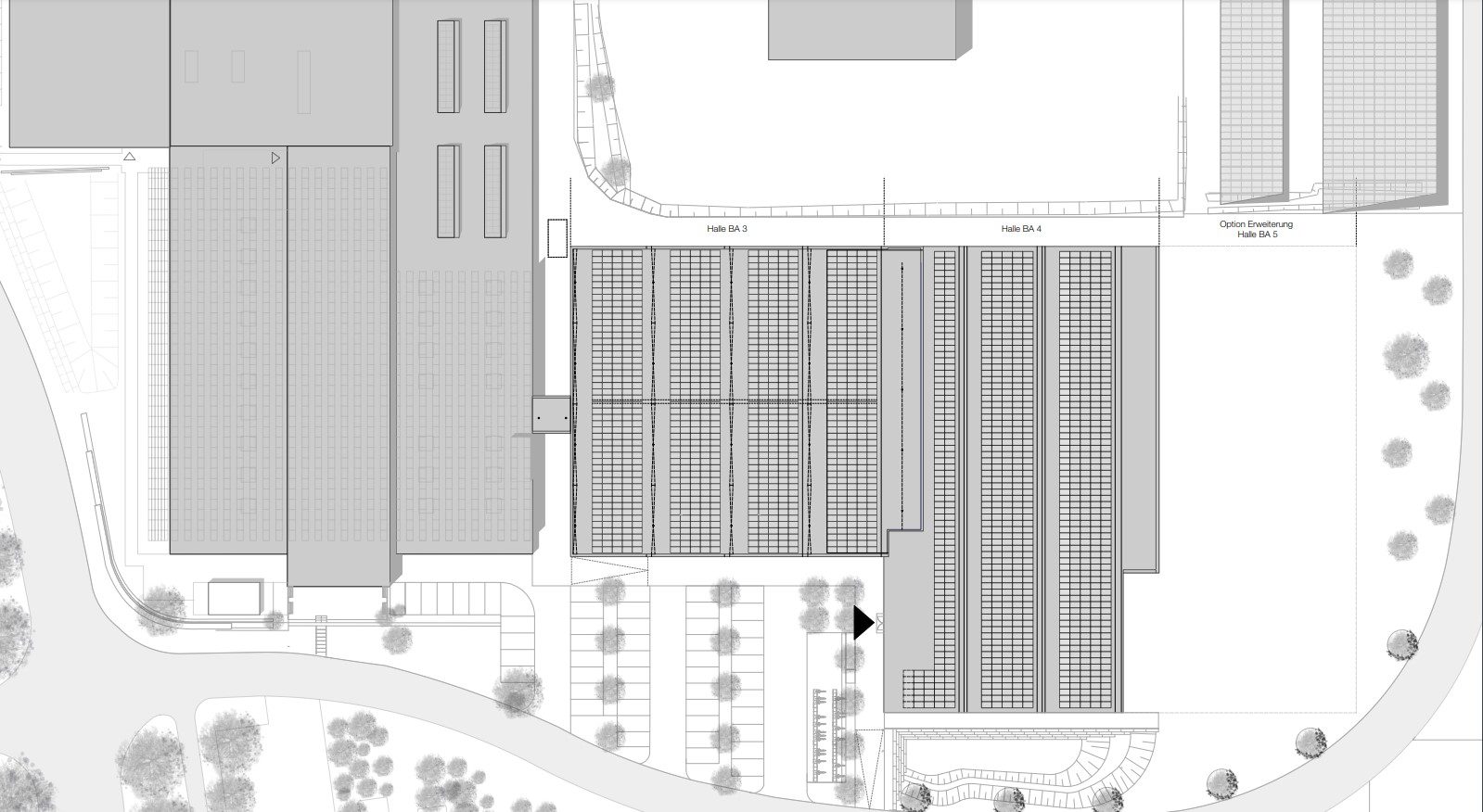

The new extension consists of two distinct sections. The first section is connected to the existing factory by a corridor, as the two buildings are only 5 metres apart. This part of the extension has a square footprint (approx. 50 m x 50 m). The adjacent second section to the north has a rectangular floorplan (approx. 38 m x 74 m) so that the entire extension is L-shaped. The wood shingle façade – a rare feature in industrial buildings – extends up to the roof. Combined with the seven saw-tooth ridges, it provides for a striking exterior architecture. The skylights facing north let in ample daylight without glare, while the inclined roof sections facing south carry photovoltaic modules that boost the energy efficiency of the hall. The photovoltaic cells cover the top three quarters of the shed roof sections, while the bottom quarter is clad with a foil that reflects daylight through the windows into the hall, making it even brighter.

The primary supporting structure of the production halls measuring around 2,500 m² and 3,200 m² respectively are reinforced concrete posts placed at distances of 12.50 m in one direction, and 12.20 m in the other. They carry the roof supporting structure of lattice girders in the steep skylight sections of the roof, as well as the rafters in the sloped shed roof sections. These rafters are at right angles to the lattice girders and secured to each other at regular intervals by means of ties and struts. The vertical and diagonal elements of the girders, as well as the rafters measuring 52 cm in height and 20 cm in width are made in BauBuche of strength class GL 75. For the top and bottom chords and the ties, the designers chose spruce glulam. BauBuche was thus used in all areas where reducing the cross-sections of the timber elements enhances the visual impact of the construction. For roof design reasons, the bottom chords of the lattice girders had to be of a certain height, as they also carry the gutters in the saw tooth troughs. They are therefore made from glulam (GL 28h) and measure 24 cm in width and 52 cm in height.

The utility cores in reinforced concrete separating the two hall sections, and the cores along the north wall serve as fire barriers and stiffening elements.

The seven lattice girders were pre-assembled at the factory and transported on special vehicles to the construction site. They were installed the moment the skeleton of the building was completed. The prefabricated reinforced steel columns were equipped at the factory with connecting plates to which the slotted sheet metal plates pre-installed in the girders were welded. These bearing blocks are rather complex metal joining plates, as they connect the concrete supports and the bottom chords of the lattice girders as well as the rafters and their tension chords. At every such block, the various loads are transferred to the concrete columns across a very small surface.

After placing and connecting the lattice girders to the reinforced concrete columns, the BauBuche rafters were inserted between the girders. Each rafter thereby runs from the bottom chord of one girder at a 15° angle to the upper chord of the next one where it is connected to a z-shaped steel bracket. The distances between the rafters are determined by the system dimensions of the lattice girders and thus correspond to the spacing of the vertical posts.

The Kerto-Q panels placed on the rafters support the waterproofing layers of the roof and form a solid plane acting as a stiffening element. The Kerto panels were equipped at the factory with wood-wool acoustic boards and an insulating course, so that it took the carpenters on site only about a week to finish each shed roof section.

Timber construction is becoming ever more popular for industrial buildings. Proprietors seeking sustainable solutions appreciate the fact that timber is a renewable resource and that the construction elements can be prefabricated to a large extent, making construction less dependent on weather conditions. Also, timber buildings offer a great indoor atmosphere that is not achievable with other materials. For the elobau factory II, the proprietor’s main reasons for choosing a timber construction were the protection of the environment and the wish to create a high-quality workspace of its employees. “We need such lighthouse projects. Together with the proprietor, we have once more demonstrated how sustainable techniques and materials can be used in the construction of commercial buildings,” says Philip Leube, architect at Büro F64. “By choosing BauBuche, we were able to expand the scope and use of timber construction methods in the industrial building sector.”

-Text by Susanne Jacob-Freitag und Nina Greve-

Geschäftsführer der Holzbau Amann GmbH

Advice for architects, building engineers, clients and timber construction companies