Locally sourced raw material from sustainably managed forests

The green alternative to reinforced concrete posts and beams.

Outstanding CO2 storage!

BauBuche stores 1.171 kg CO2 per cubic meter.

Hardwood laminated veneer lumber – known as BauBuche – enables proprietors, architects and other decision-makers to construct buildings that preserve resources, especially in multi-story post and beam construction where softwood reaches its limits.

BauBuche is a sustainable and climate-friendly construction material that allows for extra flexibility, safety and cost savings.

Today, modern production technologies enable manufacturers to produce such veneer lumber with excellent properties that offer many advantages over conventional building materials. With BauBuche, developers can erect sustainable buildings in a much more cost-efficient manner than it has ever been possible in the past.

66% lower dead weight

than reinforced concrete.

- Compressive strength like concrete C50/60

- Same column cross-sections as reinforced concrete

- Significantly smaller column cross-sections than softwood

- High surface quality

- Sustainable and ecological building material

- The high load-bearing capacity of BauBuche reduces dimensions and cross-sections in timber construction - that means more space and lower material consumption.

- BauBuche has a wide range of applications - from the smallest components to 18-meter long boards and beams.

- Easy to use as solid wood and ideal for visible construction thanks to its exceptional surface quality.

- BauBuche saves on connectors, and thus reduces costs, due to its high density and homogeneity.

- BauBuche is sourced sustainably from local forests with PEFC certification.

Beech as a hardwood has outstanding technical properties, e.g. much greater load-bearing strength than softwood, so it makes perfect sense to utilise this resource in timber construction.

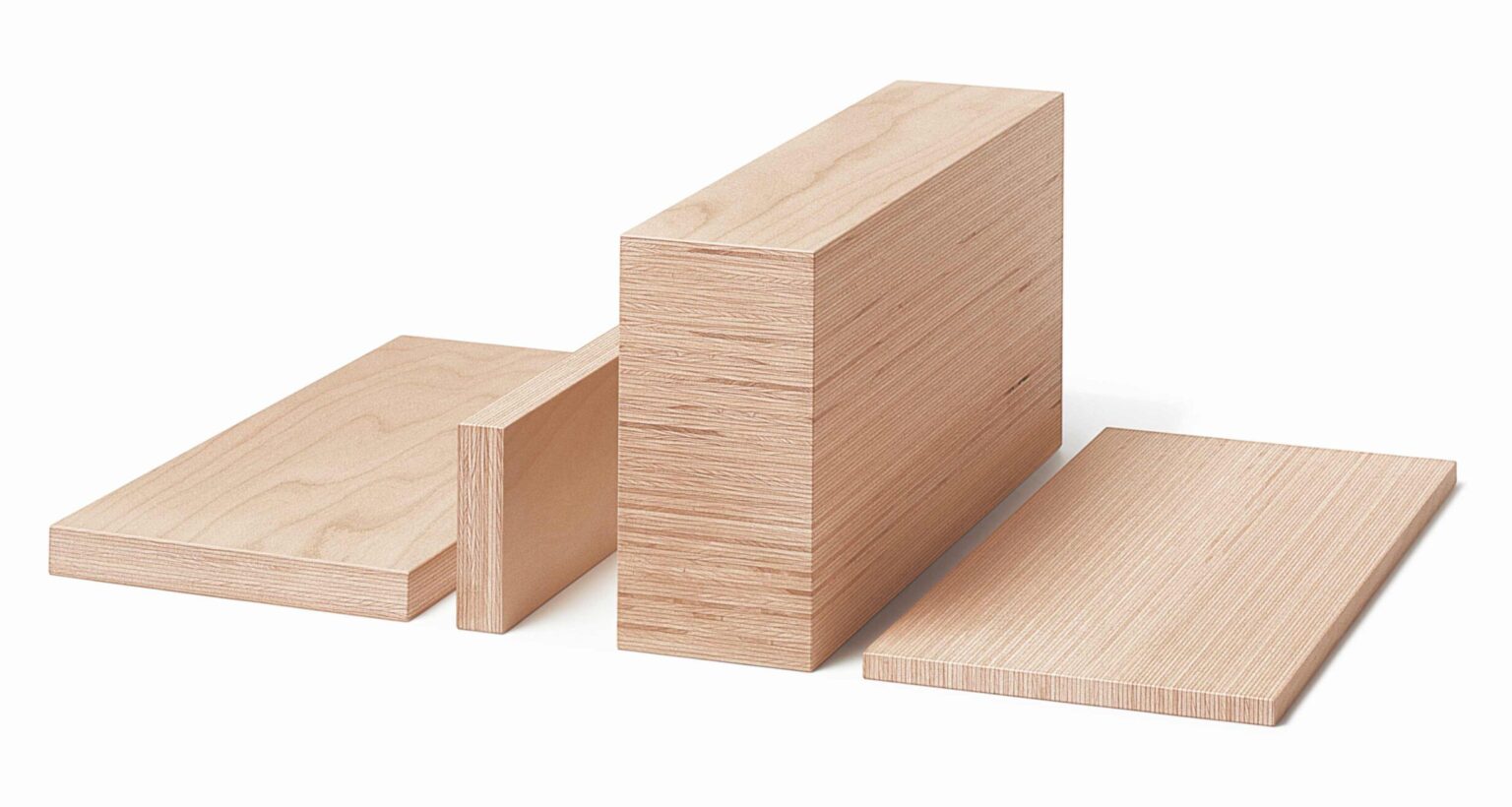

The key difference between BauBuche and other laminated veneer lumber products is the type of wood. The use of beech gives considerably higher strength than with any other LVL products, a superior surface quality and the more elegant hardwood look. Unlike plywood, BauBuche is designed specifically for use in timber construction. The veneers are therefore predominantly aligned parallel to the grain so as to give a main load-bearing direction. Another difference from plywood is that laminated veneer lumber is supplied in much larger sizes.

Beech is hardwood in plentiful supply from forestry in central Europe. At Pollmeier, the beechwood round timber is sourced exclusively from sustainably managed forests and the veneers are produced on our own peeling machine in Creuzburg, Germany.

Comparison with other building materials

| characteristic bending strength N/nm² | characteristic density kg/m³ | modulus of elasticity N/nm² | |

|---|---|---|---|

| 70 | 730 | 16.800 | BauBuche |

| 48 | 480 | 13.800 | Laminated Veneer Lumber from spruce |

| 24 | 385 | 11.600 | Glulam from spruce (GL24h) |

| 120 | 2.700 | 70.000 | Aluminium |

| 235 | 7.850 | 210.000 | Steel (S235) |

The Way of BauBuche

Advice for architects, engineers, commercial builders and timber construction:

Advice on timber, BauBuche and for Pollmeier LVL:

References

Sports, leisure and culture under one roof – as well as on top of it

BauBuche for high-performance plug-in connectors

BauBuche carries ‘Elefant’

New town hall built in BauBuche

Single materials and supporting structure concept for two sports halls

Neatly framed

BauBuche stair designs

BauBuche post and beam

Production building with BauBuche structure

Primary school with BauBuche supporting structure

Optimised timber modular construction with BauBuche

Pavilion of the future in the heart of Frankfurt

Expansion of a maisonette with BauBuche

Edeka – Using BauBuche to reduce beam height

Timber framework made of BauBuche for production plant in Vorarlberg, Austria

Interior furnishings of joinery Reim

LEVO – table and bench set with slim dimensions

Timber structure in joinery “Anton Mohr” in Andelsbuch

Library made from BauBuche

Interior design of a cinema in France

Sign up for our BauBuche newsletters now.

This way you will regularly find out everything about our products, events and the timber industry.