Since mid-2018, the Swiss company SIGA has a new production hall at the location in Schachen. Optimally integrated in the outward landscape of the existing buildings, the interior architecture reflects the innovative character of the new building. This is a result of the filigree roof construction consisting of BauBuche truss girders and glue-laminated cross beams. The use of GSA connection technology additionally enhances the effectiveness of the timber construction.

SIGA Manufacturing AG, Schachen, CH

Dubach Holzinger Architekten AG, Zürich, CH

PIRMIN JUNG Schweiz AG, Rain, CH

n’H Neue Holzbau AG, Lungern, CH

ARGE Hecht Holzbau AG & Bisang Holzbau AG, Sursee, CH

June 2018

Sibylle Kathriner // Hecht Holzbau // Pirmin Jung Ingenieure

Pollmeier, D-99831 Amt Creuzburg

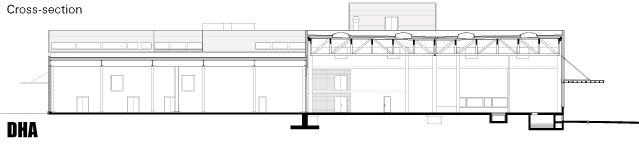

Since mid-2018 the Swiss company SIGA has a new production hall in Schachen, in the municipality of Werthenstein in the canton of Lucerne. The new hall was built as an annex to the existing buildings. The high growth in sales of SIGA products in Switzerland and Germany had led to the decision to expand the capacities. The result is a 10.65 m high hall with a ground plan measuring almost 36 m wide and 67.50 m long. In addition, an additional floor was added to the office wing. The annex was designed by Dubach Holzinger, the same architects who had erected the first production hall for the family owned company in the year 2000. They combined the production hall and office wing in a homogeneous array, with untreated, rough-hewn Douglas fir cladding. The new building therefore stands out from the surroundings with respect to its dimensions, materials and the roof profile.

Of course, it was important for the construction of the new hall to be cost-effective, which led to the question of whether or not to use timber construction. But the cost was not the only decisive factor. As a renowned supplier for timber construction systems and the window industry (tape, foils and seals) it was also necessary to document this with the choice of materials – at least to a large degree. This resulted in the decision to use a system with mixed materials: a roof construction of timber on prefabricated reinforced concrete columns.

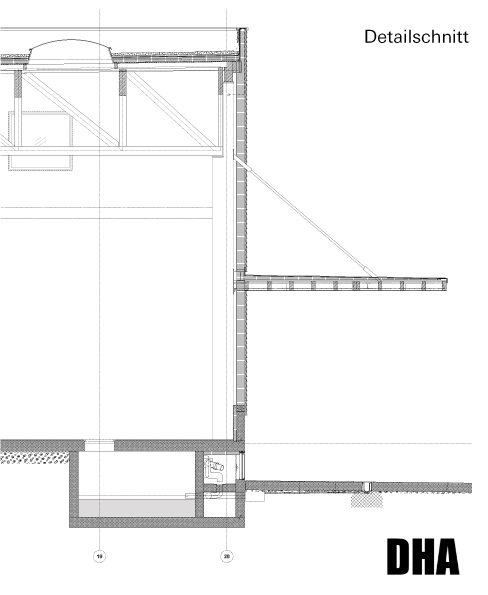

To optimally span the 36 m wide hall, the planners not only implemented reinforced concrete supports in the axes of the longitudinal walls, but also a row of centre columns. This made it possible to reduce the clear span to 18 m.

Since it is an industrial hall where the appearance is not the top priority, it was possible to use different timber types for the roof structure on the basis of the static requirements. The structural engineers at PIRMIN JUNG Schweiz AG of Rain (Switzerland) chose truss girders for the primary structure as the suitable geometry for a solution designed to be both load-bearing and architecturally appealing as well as economical; however, instead of glulam – which would have resulted in bulky cross-sections and a higher structure – they used high-strength BauBuche. The excellent mechanical strength and material properties made it possible to reduce the cross sections to create a filigree appearance despite the large span and the heavy loads from the green roof: The 17.40 m long BauBuche truss girders are therefore only 2.6 m high, with a cross section of only 30 cm by 30 cm. The height of the truss girders is even reduced to 2.40 m toward the centre support, since drainage takes place at the centre of the roof.

At a distance of 9.60 m, two single-span girders in six transverse axes span the distance from the perimeter columns to the centre columns. They are supported at the perimeter columns on the mortised reinforced concrete columns, and the upper booms connect to the glulam edge beams, which extend in the longitudinal axis over the mortised reinforced concrete column heads. At the lower support point of the cantilevered truss girders, both the reinforced concrete columns and the lower booms were equipped with steel plates at the factory. These plates were then welded together during construction at the site.

For the cross beams of the secondary structure the planners then used glue-laminated spruce and fir timber.

An important element of the roof construction is the so-called GSA technology (GSA = “Gewinde Stangen Anker”), a threaded steel rod anchor system. The positive-locking connection system was developed by the “Neue Holzbau” company of Lungern, which also manufactured and delivered the timber structure. The system consists of bonded steel connectors, which feature high strength and rigidity, as well as good ductile properties, and are designed for fast and easy installation at the construction site. This is especially advantageous with the use of BauBuche, which despite its high load-bearing capacity is not specially designed for on-site processing. At the connecting points of the cross beams, two GSA rings were inserted on the trusses and a steel connecting component specially developed for this project was used on the truss beams. This design allows easy connection at the construction site in the form of a simple plug-in connection held by a bolt. GSA technology was also used in the manufacture of the BauBuche truss girders. Instead of slotted steel sheets with dowel connectors, all truss joints were implemented with GSA connectors.

For the transfer of tensile and compressive forces the truss girders are equipped with six diagonal braces and seven perpendicular studs. The latter are connected to the cross beams, for optimal transfer of the loads from the secondary structure to the columns via the main structure. When viewing the row of centre columns construction from the side, crosswise to the longitudinal direction, every second field has a diagonal brace leading from the head of the reinforced concrete column to the cross beam, enclosing the latter like pincers. The function of these diagonal braces is to fix the truss girders on the columns, so that the connecting point does not function statically as a hinge.

Assembly of the hall took place one field at a time: After positioning six prefabricated reinforced concrete columns, the corresponding truss girders were connected. This was followed by fastening of the cross beams. To create a flush-mounted connection the cross beams were lowered by the thickness of the roof elements in relation to the top edge of the truss girders.

In Switzerland, there are no legal fire safety requirements for single-storey halls. Nevertheless, the owner installed a sprinkler system in the hall.

The completely prefabricated wall, ceilings and support elements made it possible to erect the production hall in only four weeks. The total planning and construction time was 14 months.

-Text by Susanne Jacob-Freitag-

Geschäftsführer der Holzbau Amann GmbH

Advice for architects, building engineers, clients and timber construction companies