Pollmeier built a new warehouse at its company headquarters in Creuzburg.The roof structure is made entirely of timber and consists of BauBuche lattice girders and purlins, and spruce LVL boards. The purlins and boards are assembled to form roof elements that act as stiffening plates so that there is no need for additional wind bracing.

Pollmeier Massivholz GmbH & Co. KG

+Seelinger Architekten+Ingenieure, Darmstadt DE

Holzbau Amann GmbH, Weilheim-Bannholz DE

sblumer ZT GmbH, Graz AT

270 m³ BauBuche

165 m³ Pollmeier Spruce LVL

4.300 m²

Pollmeier, D-99831 Amt Creuzburg

“For the roof of the new ‘Flächenlager West’ of Pollmeier in Creuzburg, we could have opted for a standard construction with steel or reinforced concrete lattice girders combined with a trapezoid sheet metal covering,” explains the architect Martin Seelinger. “Pollmeier however felt that the new building should be a timber construction – in line with its existing production halls.” As BauBuche lattice girders have been successfully used in various hall projects designed by well-known architects for a number of renowned companies, it was only logical that Pollmeier should opt for this type of construction for its own storage hall.

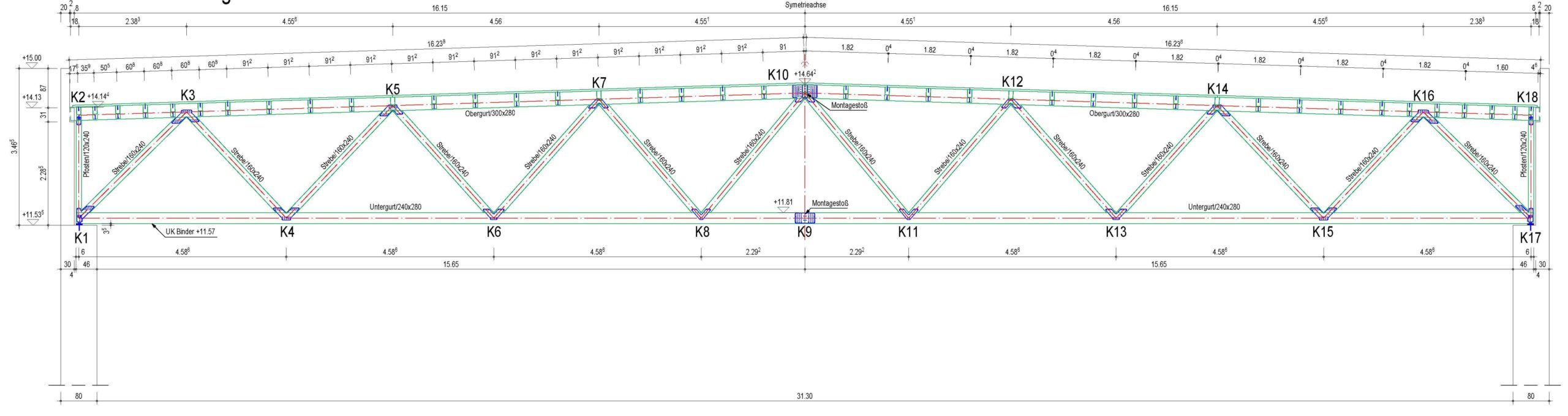

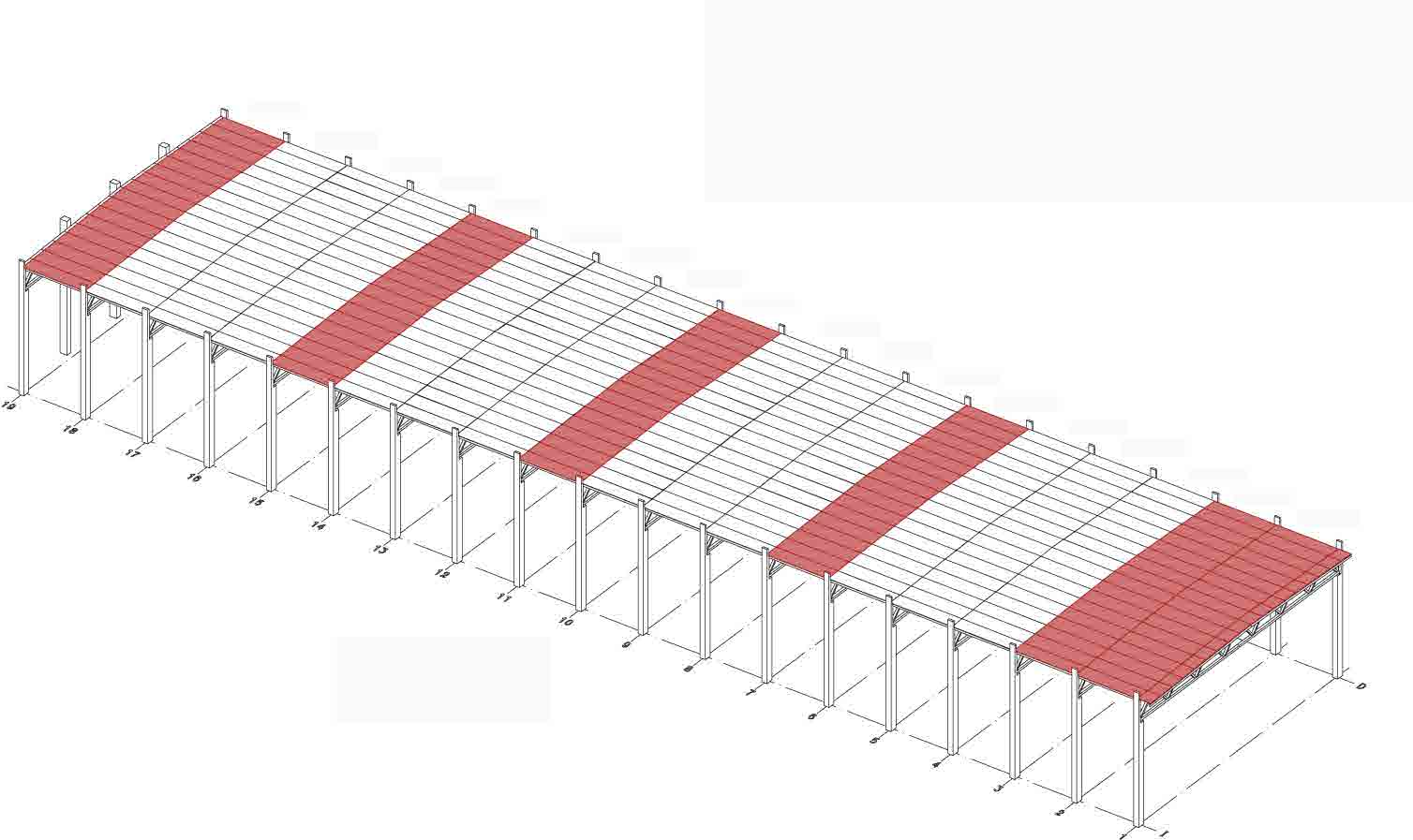

For the static system, the engineers chose a “beam-on-two posts” construction in a linear arrangement. The BauBuche lattice girders rest on precast stressed reinforced concrete posts positioned 7.20 m from each other that form the load-bearing skeleton structure of the storage hall measuring nearly 33 m in width, 131 m in length and 15 m in height. The trusses are just under 32 m long. For manufacturing and transport reasons, they consist of two separate parts that are joined together on site, using a special fastening system with slotted sheet metal plates and steel dowels (BSB connectors). For drainage, the upper chords are installed at a slight slope of 2% towards the gutters. At the centre assembly joint, the lattice girders are therefore just below 3.10 m high, tapering to 2.60 m at the gutters.

The precision-machined parts of the trusses were pre-fabricated by Pollmeier in Creuzburg and shipped as kits of “roughs” to the timber construction firm Amann. There, the components were cut to size in a CNC machine, where the slots for the sheet metal fasteners and the dowel holes for the nodes where produced.

For the actual roof, Pollmeier also opted for timber as the main material. It consists of Pi board elements produced from BauBuche purlins and screw-mounted spruce LVL boards (LVL = laminated veneer lumber). These elements have the advantage that they can be joined together to a plate, doing away with additional wind stiffening assemblies, which would not have been an option with a standard trapezoid sheet metal roof covering.

With regards to production and installation, Pi boards proved an ideal solution: the purlins were easy to join and could be quickly screwed together with the 39 mm LVL boards to form the load-bearing elements that bridge the 7.20 m span between the lattice girders. Their width of 1.82 m is given by the standard dimensions of the Pollmeier LVL boards. This allows for Pi board elements with three purlin beams at distances of approximately 90 cm, i.e. one at the centre and two at the outside. To prevent double beams along the longitudinal joints, the designers omitted one edge beam in each element. The boards extend across half the width of the edge beam of the adjacent element, and are secured with screws to that beam. As the elements are installed in rows, the protruding board side is placed on the beam of the adjacent element and screwed to it. This method allows for the step-by-step installation of a roof construction in the form of a continuous Pi board. As the joints are positioned on top of the purlins, the construction does not require coupling plates at the board joints, so that less material is required, saving money.

The ends of the roof element purlins are equipped with tenons that fit perfectly into the mortises along the sides of the upper chords of the lattice construction. This joining method does away with costly fasteners and additional screws. When the elements are put in place, the front edges of the LVL boards come to rest on the top chords of the lattice structure to which they are then secured with screws. Following best practice, all BauBuche components are fastened with officially approved screws.

As the roof construction only requires stiffening plates in certain fields, the boards of elements in other areas can be safely cut out to cater for chimneys, flues, roof lights and similar features. For openings that are larger than the distance between the purlins, there is no need to cut these. In such cases, it is sufficient to extent the opening in the board cover by the cross-section of the purlin. In this manner, it is for instance possible to produce relatively large openings as are required for flues.

In total, around 324 roof elements were installed. Given their high load-bearing capacity, they are a most economical solution, saving resources. When completed, the new warehouse will be used primarily for the storage of beech and spruce LVL boards. For the handling of the goods, Pollmeier will install crane tracks on which fully automated vacuum lifting systems will run along the entire length of the hall.

-Text by Susanne Jacob-Freitag-

Geschäftsführer der Holzbau Amann GmbH

Advice for architects, building engineers, clients and timber construction companies