With the recently completed six-storey office building called “i8” on the iCampus, the new “Werksviertel” district of Munich has received a special kind of timber hybrid building: From the very beginning, the well-being of employees was at the heart of the planning. BauBuche is playing a significant and supporting role in this.

R&S Immobilienmanagement GmbH, D-81671 Munich, Germany, www.rusim.de

C.F. Møller GmbH, DK-2200 Copenhagen, Denmark, www.cfmoller.com in collaboration with RKW Architektur+, RKW Architektur + Rhode Kellermann Wawrowsky GmbH, DE-40474 Düsseldorf, Germany, www.rkwmail.de

merz kley partner, A-6850 Dornbirn, Austria, www.mkp-ing.com and BWP Ingenieure GmbH, D-80807 Munich, Germany, www.bwpgmbh.de

Eder Holzbau GmbH, D-83075 Bad Feilnbach, Germany, www.eder-holzbau.de

Pollmeier Massivholz GmbH & Co. KG, D-99831 Creuzburg, Germany, www.pollmeier.com

2020 to 2025

12/2022

06/2023

03/2024

approx. 06/2025

Yohan Zerdoun Photography, D-79114 Freiburg, www.yohanzerdoun.com

merz kley partner, A-6850 Dornbirn, www.mkp-ing.com

Eder Holzbau GmbH, D-83075 Bad Feilnbach, www.eder-holzbau.de

C.F. Møller GmbH, DK-2200 Kopenhagen, www.cfmoller.com

merz kley partner, A-6850 Dornbirn, www.mkp-ing.com

R&S Immobilienmanagement GmbH, D-81671 München, www.rusim.de

A new district, the Werksviertel (Factory Quarter), is being built around Munich’s Ostbahnhof (East Station). Innovative working environments, i.e. offices based on new work concepts, will be found here, as will restaurants, shops, art and leisure activities. The motto is “Work-Live-Quarter”. One of these buildings is the i8, a six-storey office building constructed using a hybrid timber construction method. Commissioned by R&S Immobilienmanagement GmbH, the renowned Danish architectural firm C.F. Møller developed a building in which not only sustainable construction but above all spaces with a high level of livability were important. In keeping with the spirit of the district, the well-being of the users at the heart of the design took centre stage for the client, in line with a holistic understanding of health. The use of wood for the visible supporting structure, for panelling, windows and doors, created a pleasant, harmonious atmosphere with a healthy indoor climate.

Six-storey U-shape encloses a building-high atrium

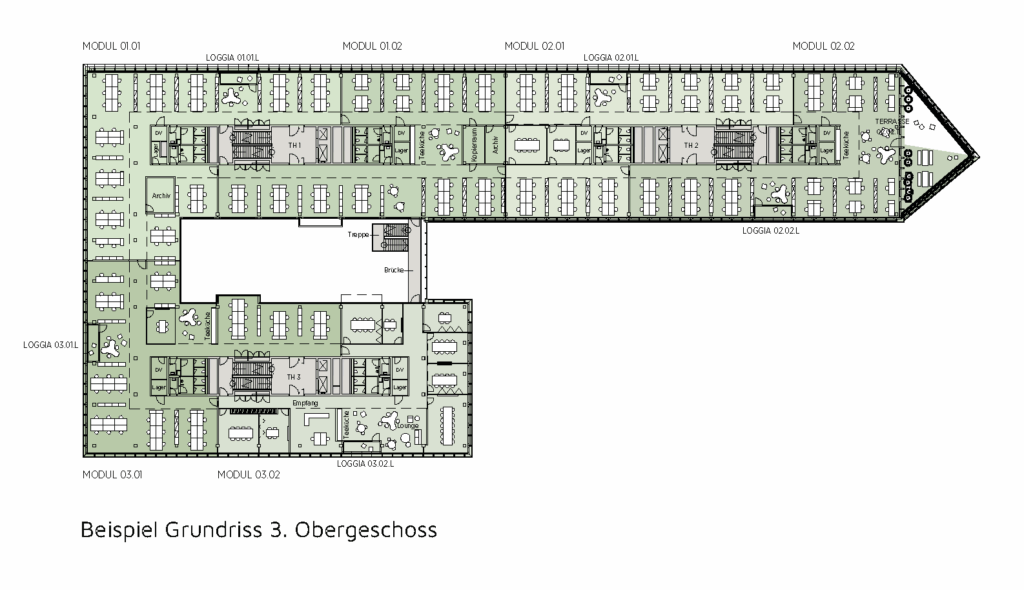

The 23 m high, six-storey building with a total floor area of 20,000 m2 was completed in only around nine months thanks to the high degree of prefabrication. With a footprint of approximately 3,600 m2, the building is shaped like a horizontal U with sides of different lengths. The northern wing is 115 m long, more than twice as long as its parallel counterpart at 49 m. The former ends in a rectangular point, which in turn is only three storeys high, but has a roof terrace. All other areas are six storeys high.

These two approximately 19 m wide wings have been placed at a distance of about 11 m from each other. Together with the approximately 12 m wide cross beam, they enclose the interior U-shaped space, which serves as an atrium, as far as the length of the short leg. Each wing is accessed lengthwise via a central reinforced concrete block which, in addition to staircases and lifts, also houses sanitary facilities and additional lounges and meeting rooms. Corridors lead to the offices arranged on both sides whose space can be flexibly divided so that each floor can be divided into between one and six rental areas. Within the floors, the areas can be organised with individual and team offices as well as communication areas. The timber frame construction made of highly load-bearing BauBuche pillars and beams enabled the desired open office structure based on a construction grid in the building’s transverse and office space longitudinal directions of 5.40 m.

In addition to the office spaces with ceiling heights of around 3 m, the i8 with its atrium also offers an event space for up to 600 people. This atrium, which extends over all six floors, is particularly distinctive. The bright, open space offers many opportunities for informal encounters on wooden steps, “floating” stairs and bridges. The space is further enlivened by large wooden frames that appear to extend from the interior façade into the airspace. Galleries and loggias further lighten up the interior façade. Plenty of daylight, wood and glass provide a friendly, inspiring welcome for those arriving. The architects describe their design approach, which won them a competition in 2020, as being intended to facilitate networking, knowledge sharing and visual contact between the various floors and units.

Slim BauBuche components with many wood-to-wood connections

Without BauBuche, the timber construction project with such slim cross-sections and simple connections would not have been possible. Although the building could have been constructed in a similar structure using “classic” spruce glued laminated timber, this would have required significantly larger cross-sections – particularly for pillars and main beams – and more complex connection details with more steel or more steel connectors. The high load-bearing capacity of the BauBuche beechwood not only made it possible to create smaller cross-sections but also to design many details as wood-to-woodconnections, where the load is transferred directly via wood contact.

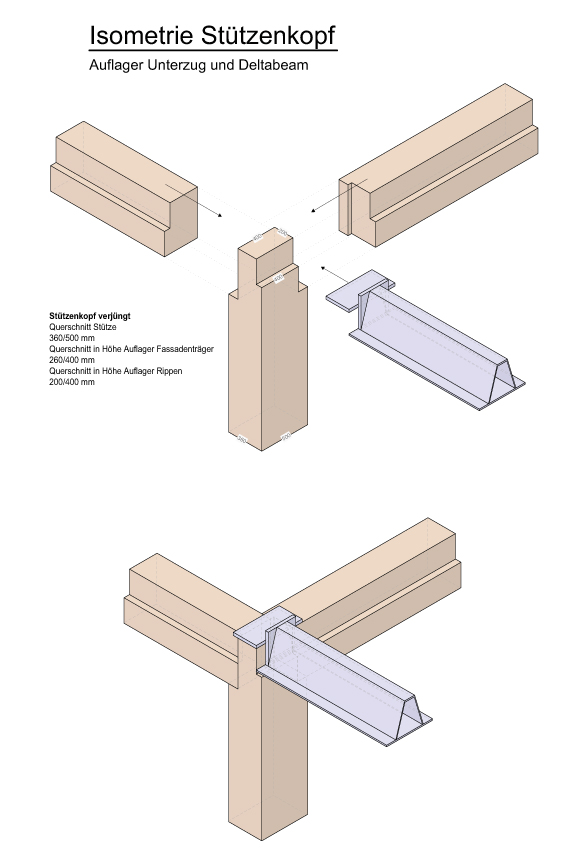

Apart from the two elongated reinforced concrete access cores inside the two building blocks, virtually all load-bearing components such as pillars, façade supports and main beams as well as joists are made of BauBuche. Reinforced concrete composite beams (Peikko Deltabeam) were used only at the corners of the building to accommodate the change in the span direction of the timber-concrete composite ceilings. Accordingly, the structural engineers used Deltabeam composite girders on the west side of axis 2. However, in axis 3, at the atrium, due to a lack of supports, they chose a 12 m wide steel box girder as a suspended or support beam. In combination with steel tension rods, the loads could be guided upwards towards the roof and then onto the corner supports of the atrium. Overall, the structural engineers placed great emphasis on transferring the loads wherever possible through pressure connections, i.e. the wood-to-wood connections mentioned above, in order to reduce the number of connectors.

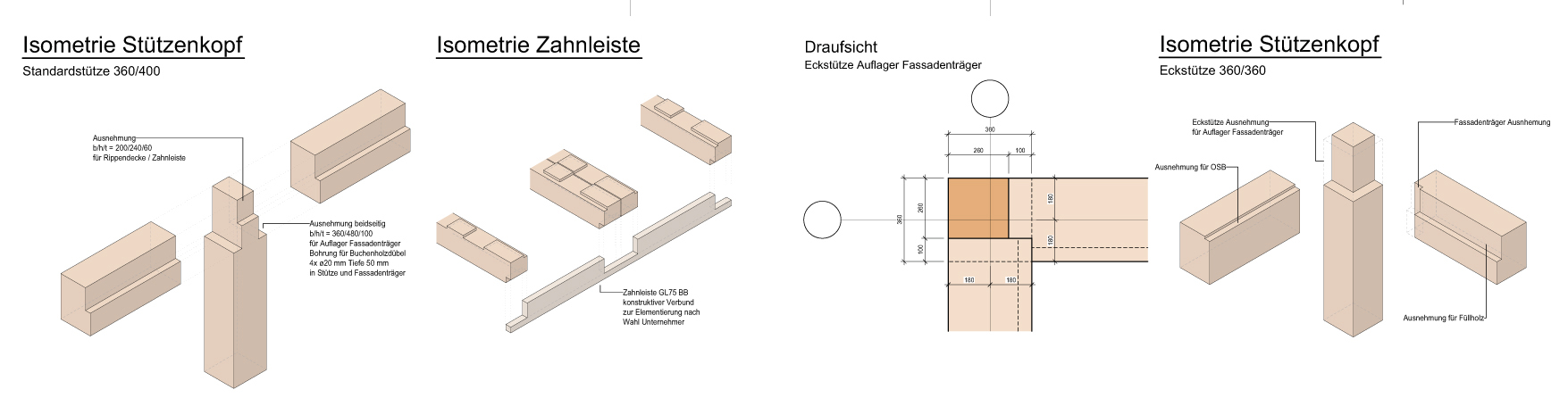

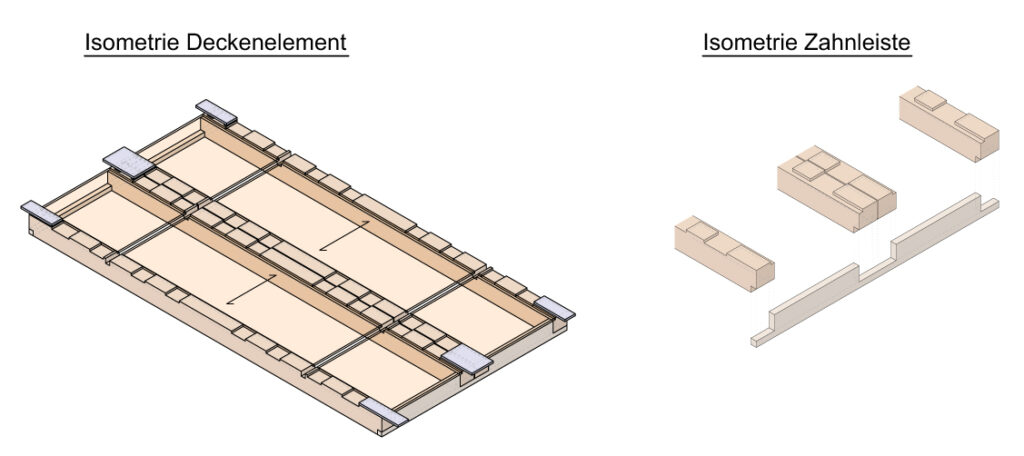

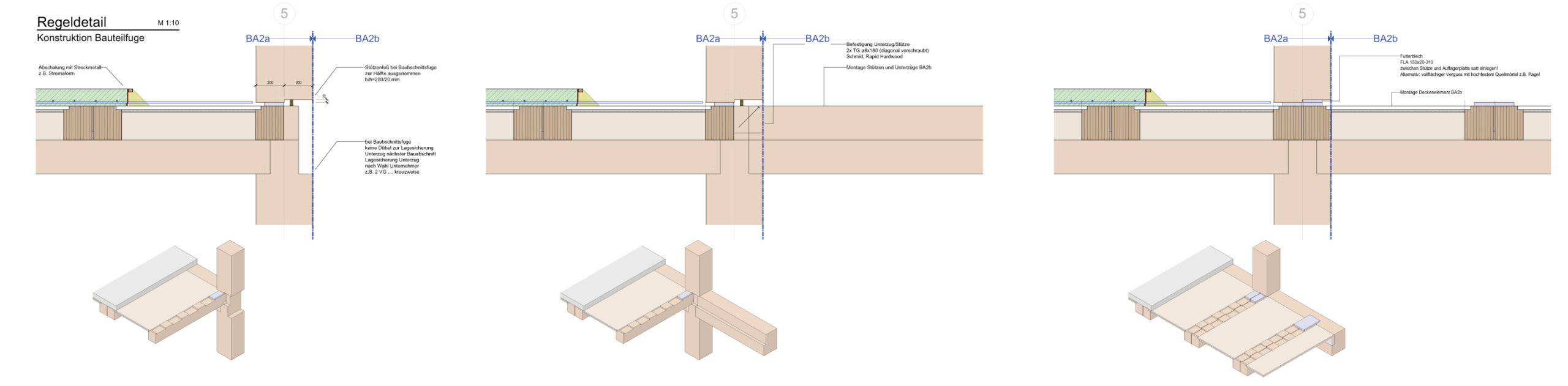

The ceilings between floors are constructed with wood-concrete composite elements in the form of ribbed slabs. During assembly, the core was constructed first, consisting of reinforced concrete ceilings on reinforced concrete pillars and, in the area of the sanitary facilities, also reinforced concrete walls. This was followed by the placement of the approximately 4.50 m high BauBuche pillars with dimensions of 36 cm x 40 cm on the ground floor, secured by temporary bracing. BauBuche beams measuring 36 cm wide and 48 cm high were then laid on the supports in the façade axes. Finally, the “wooden part” of the wood-concrete composite ceilings could be suspended element by element between these façade beams and the solid core, the reinforcement inserted and the cantilevers of various sizes prepared. Each ceiling element includes four BauBuche beams (W x H = 20 cm x 24 cm), one on each of the external long sides and one double beam in the middle. The concrete side of the elements is covered with chipboard (LivingBoard P7). BauBuche toothed strips grip the elements at the end faces and ensure the necessary stability of the ceiling elements during transport and installation. Before theconcrete for the wood-concrete composite ceilings on the ground floor could be poured, appropriate supports had to be installed under the ceiling. According to this principle, the building was constructed floor by floor.

But even if the approach was basically the same, the details differ according to the respective requirements: along the staircase in the atrium, at the corners of the building, at the building joint and of course at the connections to the solid core or at the support of the bridge in the atrium as well as the connection to the reinforced concrete composite girder (Deltabeam).

One typical detail is the intersection on the façade side on one of the 36 cm x 40 cm standard supports, to which the façade beams are connected in the façade axis, in which the beams were given a 10 cm notch on both sides so that the beams can rest on them. Their position is secured by beechwood dowels. In addition, both the pillars and the façade beams had to be notched so that the ribbed ceiling elements could also rest on them for assembly. In the final state, and especially in the event of a fire, the ceiling elements rest on the façade beams and the reinforced concrete core via steel plates screwed on top. The pillar of the floor above stands on these steel plates and is secured in position by steel angle connectors.

The connection point of the 33.5 cm high Deltabeam girder is completely different, with a cantilever plate welded to the front of the girder between the BauBuche supports, to name just one example. At the support of the wood-concrete composite elements on the solid core, the BauBuche ribs abut the reinforced concrete ceilings with a narrow joint. These are notched in such a way that the concrete layer of the wood-concrete composite elements, reinforced by steel components, rests here.

The façade

While wood and glass dominate the internal architecture, the building’s exterior features a striking façade made of green aluminium struts. This can be seen, among other things, as a connection to the former railway and industrial site. The shade of green chosen is DB601 Green, the shade still used by Deutsche Bahn (German Railways) to paint certain elements such as masts, bridges or barriers. The aluminium itself is made of 75% recycled end-of-life aluminium, the production of which requires only a fraction of the energy required to produce primary aluminium.

Economical timber construction with space savings

Last but not least, the increase in space in an office building of this size due to the use of BauBuche is remarkable. The highly load-bearing hardwood allows for very slim pillar dimensions despite high loads. In total, the space gained in the i8 – compared to using pillars made of spruce glued laminated timber – amounts to 64 m2. Depending on the price per square metre for office space, this can sometimes result in remarkable added value, which for a building as large as the i8 can run into hundreds of thousands – an amount that should make every developer and investor sit up and take notice, not to mention the aesthetics of a timber structure made of BauBuche, which is of course a priority in the design and planning.

text by: Susanne Jacob-Freitag, Karlsruhe

Please note: The article is protected by copyright. For use or publication, please contact Pollmeier or the author.

Geschäftsführer der Holzbau Amann GmbH

Advice for architects, building engineers, clients and timber construction companies