Since 2017, the Annweiler Ecumenical Social Station in the Bad Bergzabern Castle (Rhineland Palatinate) has a new banquet hall. Integrated in the courtyard of the listed building, the newly constructed hall, which is implemented in BauBuche, rejuvenates the existing structure without being obtrusive.

architekturbüro ruser + partner mbb, Karlsruhe

Haag Ingenieure, Ettlingen

Zimmerergeschäft Wissing, Kapellen-Drusweiler

Pollmeier Massivholz GmbH & Co.KG

8 m3

107,5 m²

2017

Pollmeier, D-99831 Amt Creuzburg

Hannsjörg Pohlmeyer

Since there was no suitable room anywhere in the existing building, it became necessary to expand the social station’s facilities to include a meeting and banquet hall. This led to the idea of building a clear-span annex in the courtyard of the medieval castle. That the annex, which has a width of 8.60 m, a length of 12.50 m, and a height of about 4.25 m, would be a timber construction was decided early on, due to the advantages offered by the high level of pre-fabrication. After considering various timber support variants for implementing the architects’ design, the engineers finally chose a construction using the highly stable material BauBuche, enabling very small cross sections – which is a decisive criterion in such a small hall. The use of BauBuche also facilitated compliance with the fire safety requirements F30 easily, due to the dimensions of the beams and posts.

Regulations for the protection of historic landmarks made it necessary to design the hall as a self-supporting structure, independent of the existing building. Although two sides are connected by construction elements, the new building is fully self-supporting.

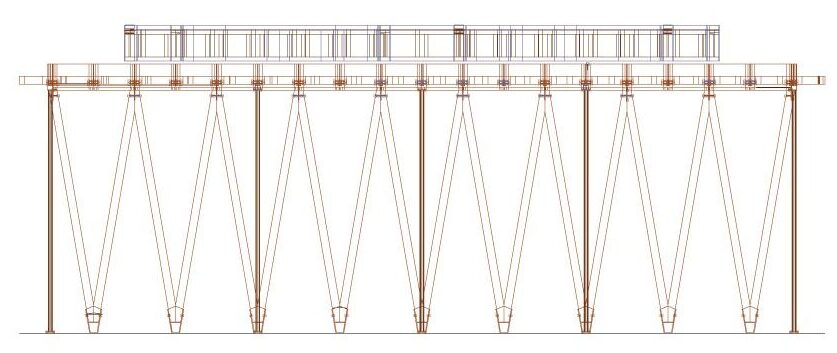

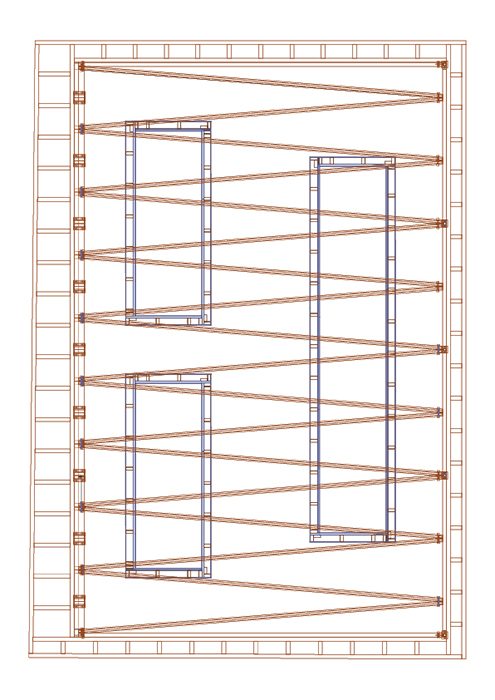

The construction of the banquet hall consists of five very narrow round steel posts on the longitudinal side of the room to the left of the entrance – steel was chosen due to the location of one of the posts in front of one of the narrow sandstone windows – and on the opposite side of a series of nine V-shaped posts made of BauBuche (12 cm wide x 20 cm high). They are arranged next to each other so that the tops of the posts meet the adjacent V-posts to form a type of accordion structure, which creates a very effective reinforcement in the longitudinal axis.

The principle of the zigzag beams was also used for the supporting level of the ceiling and roof. In this construction the points of the zigzag line of the roof are supported by the tips of the zigzag line that form the V-shaped posts. Again, the resulting triangular shapes were used to optimal static effect, which made it possible to achieve the reinforcement with the 40 cm high and only 8 cm wide BauBuche beams, instead of using the usual construction with OSB panels held in place by screws. The chosen roof construction also facilitated the inclusion of skylights in the roof design, which would have been too large for a reinforcing pane. This also made it possible to install the supporting layer of the waterproofing level for the flat roof independent of the beams.

The bottom points of the V-shaped posts are anchored in cast steel base elements that are bolted directly to the concrete floor by means of heavy-duty anchors. More complicated are the connecting points of the mitred diagonal posts on the outer roof edge beams: Likewise 40 cm high and 8 cm wide, these beams are connected at the mitred roof beams by means of steel profiles with perforated sheet metal elements, using rod anchors. These perforated sheets were also extended downward in the manner of a strut to enable connection of the BauBuche posts. This construction not only conceals all steal elements, but also fulfils the fire safety requirements.

The roof beam level is followed by a layer of three-layer panels with open spaces for the three box-framed skylights. The panels serve as the basis for the green roof.

If one looks through the windows from above, one sees the diagonal roof beams. Standing in the room, the BauBuche roof beams with the three-layer spruce panel enhance the design of the room as the ideal supplement to the V-shaped posts.

The use of hardwood, such as BauBuche, also involves special machining requirements. This is pointed out by Pollmeier to the respective contractors during the planning stage of a project. In this case, the special properties of the wood were relevant due to the requirement for grooves in the bottom of the beams for LED light bands.Routing the grooves in the 8 cm wide beams requires a high degree of precision and caution to prevent the wood on either side of the groove from being damaged. Having been perfectly implemented, the grooves provide an aesthetic detail that allows the light bands to achieve their full effect.

The special nature of the construction site posed somewhat of a challenge with respect to logistics. Since it was impossible for motor vehicles to enter the courtyard, the roof frame with the V-shaped supports was constructed on an adjacent parking lot and then lifted into the courtyard by means of a crane. Inside, the foundation had already been poured as a separate element from the existing building. The roof structure was first placed on an assembly construction to allow the V-shaped supports to be pushed from below into the struts already mounted on the roof edge beams. Otherwise it would have been virtually impossible to fit the roof construction simultaneously in all slots of the beams.

The feet were placed in the base elements and levelled with shims, after which the base elements were bolted to the BauBuche elements and anchored to the foundation. This was followed by the floor construction of the self-supporting meeting and banquet hall.

-Text by Susanne Jacob-Freitag-

Geschäftsführer der Holzbau Amann GmbH

Advice for architects, building engineers, clients and timber construction companies