All the details on the office building by lattkearchitekten BDA:

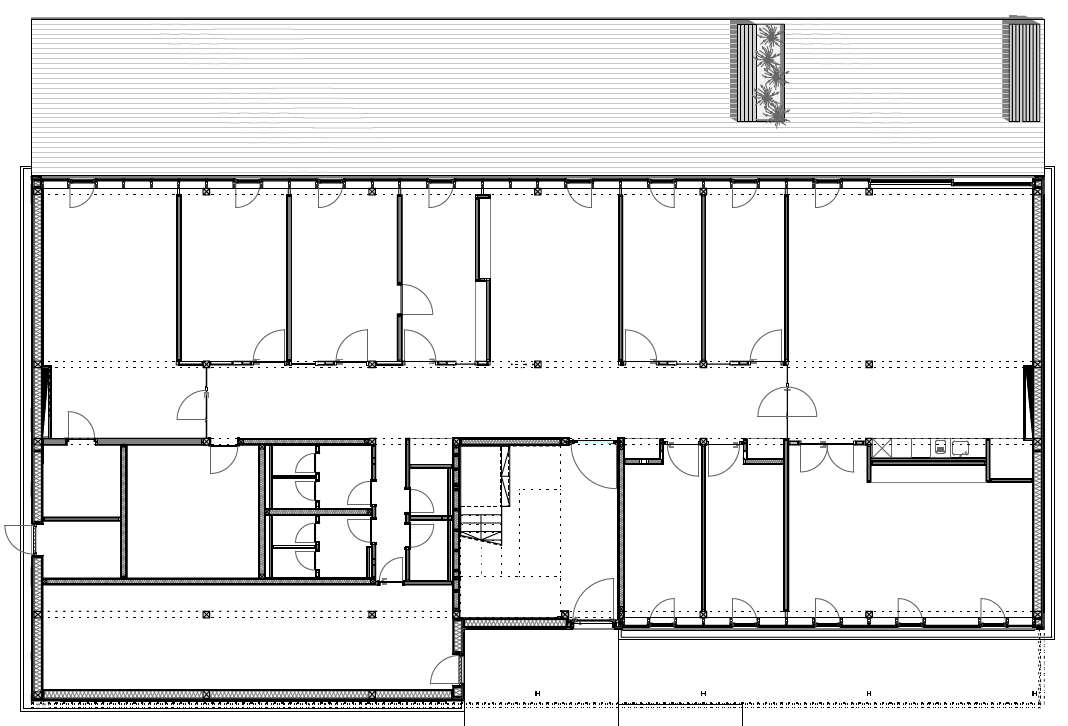

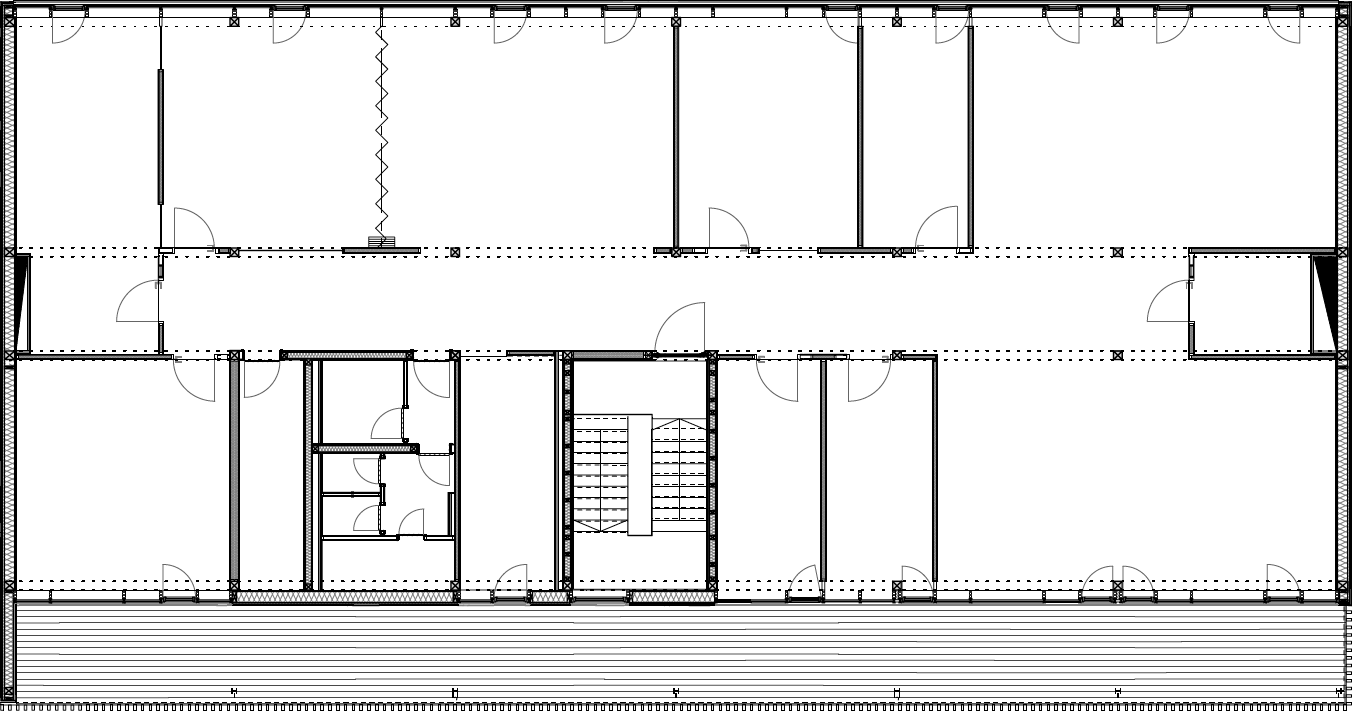

The light timber surfaces of the post and beam structure with visible columns and beam ceilings shape the overall feel of the room and create a pleasant working environment. The occupier has created room zones of different sizes to suit the workplace requirements. The dividing walls and wall panels in glass and white opaque surfaces follow the structural design and subtly allow visual contact between the adjacent rooms.

The 2 metre wide balcony on the southern side adds extra space and also creates a protected and attractive outdoor area in the close proximity of the park itself. The shade created by the overhang prevents the sun shining directly in, so no technical sun protection is required.

Augsburg, Walchstraße

2014-2015

3

lattkearchitekten BDA, Augsburg

bauart konstruktions GmbH, München

JETTER Ingenieur- und Service GmbH & Co. KG, Gersthofen

Gumpp & Maier GmbH

2.783 m²

465 m²

1.335 m²

4.690 m³

310.88 m²

20×152 mm

Hardwax oil

No. 100

Glued to screed

The BauBuche frame construction of euregon AG won the HolzBauPlus award in the category for new commercial buildings. This prestigious competition takes place every two years under the auspices of the German Federal Ministry of Food and Agriculture and aims at promoting sustainable building methods and materials. Congratulations!

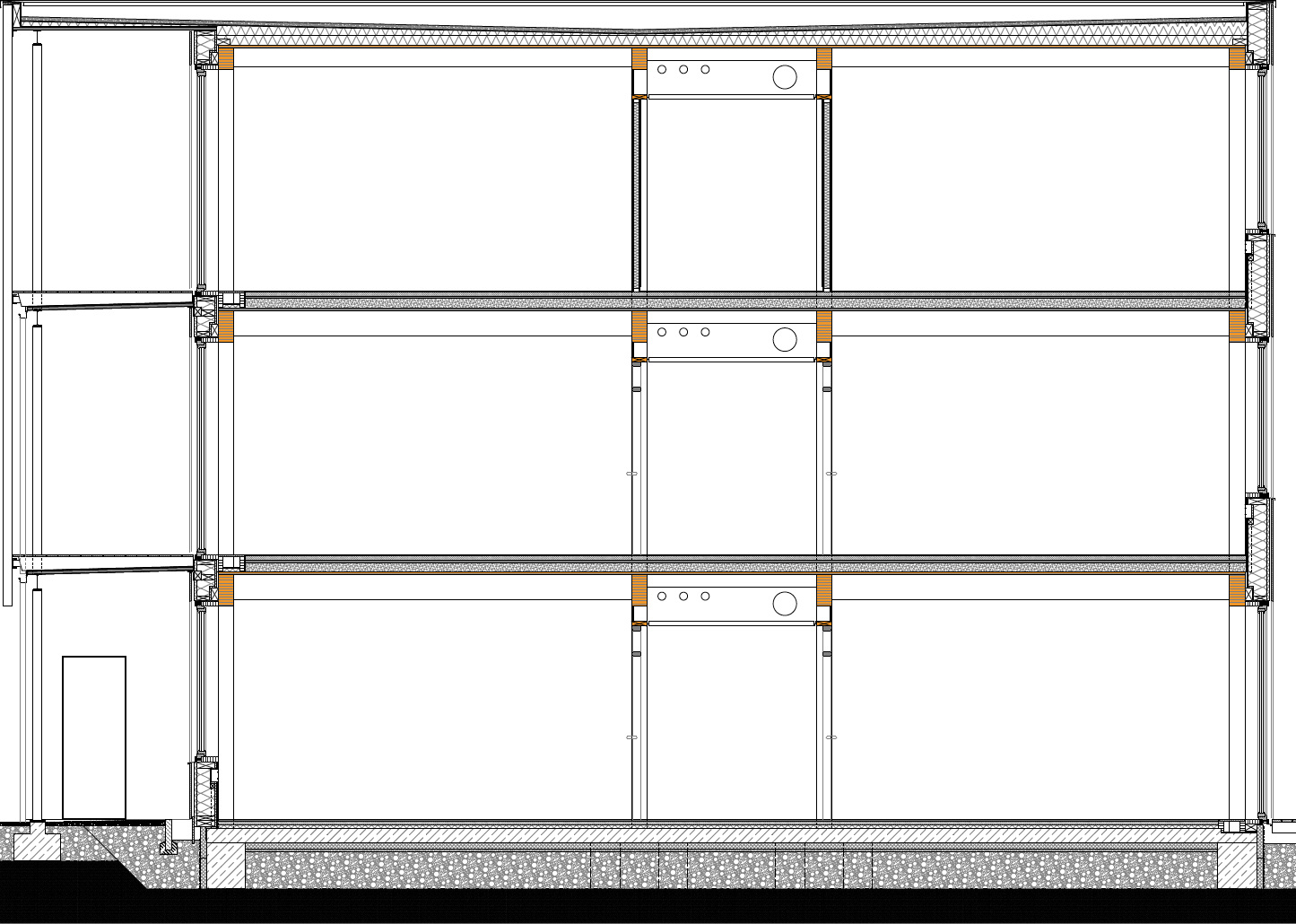

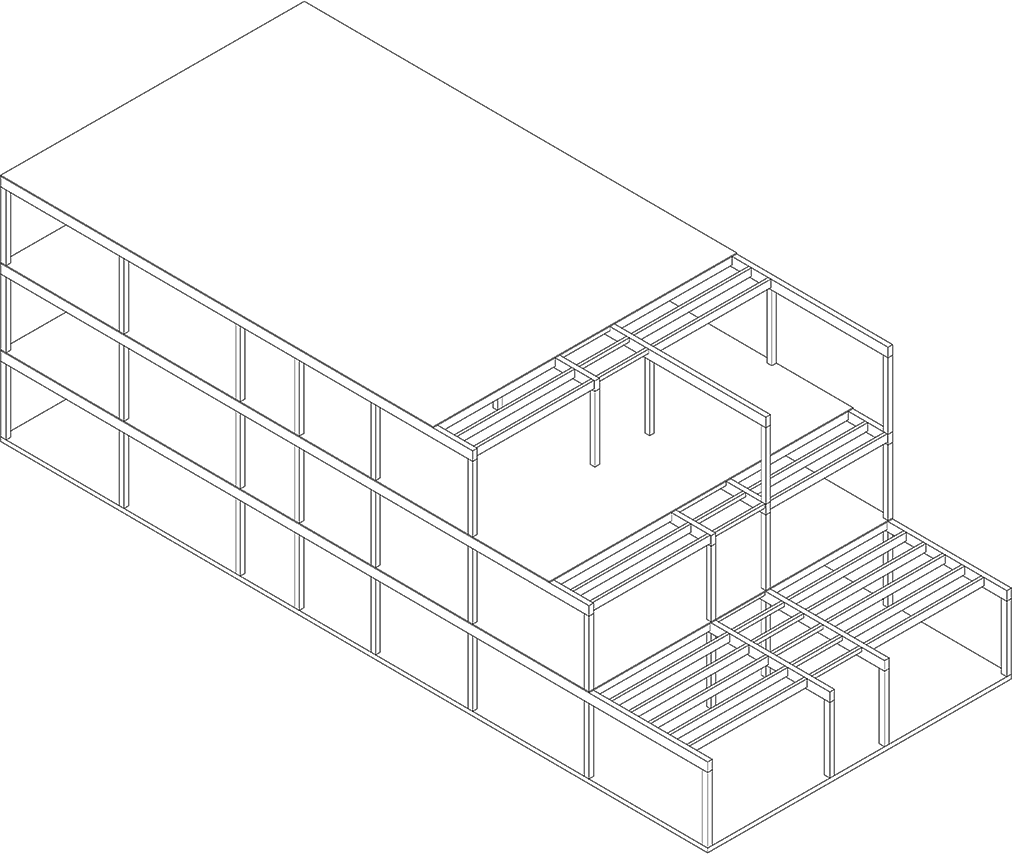

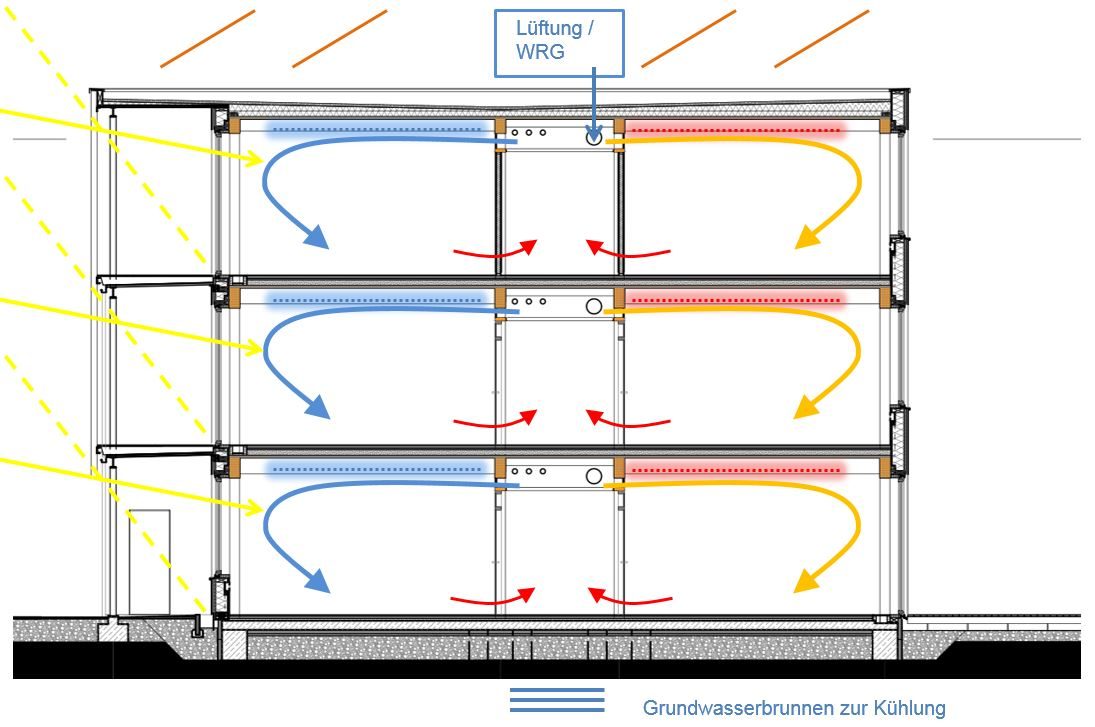

The main post and beam structure forms a room zone measuring 5.1 m in depth on the north side and another on the south side plus a 2.4 m wide central corridor, where the building’s main supply for ventilation, heating and air-conditioning is located in the suspended ceiling.

A mullion and transom façade with triple glazing, also made of BauBuche, is positioned in front of the column level.

| Columns: | Grid: 5, 10 m; BauBuche GL70 (20/20 cm) |

| Main beam: | BauBuche GL70 (20/40 cm) |

| Secondary beam: | Grid: 85 cm; BauBuche GL70 (12/32 cm) |

| Ceiling board: | BauBuche Q (40 mm) |

| BauBuche flooring: | 20 mm |

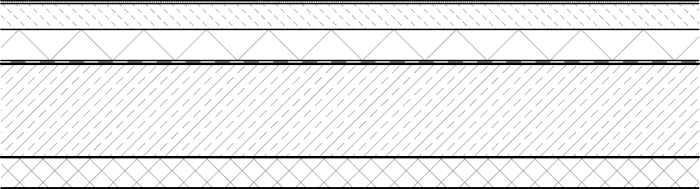

| Cement screed: | 54 mm |

| Insulating board, soft wood fibre: | 40 mm |

| Bituminous seal: | 6 mm |

| Reinforced concrete floor slab: | 180 mm |

| PE film separating course: | 0,4 mm |

| Insulation XPS: | 80 mm |

| Cement screed: | 50 mm |

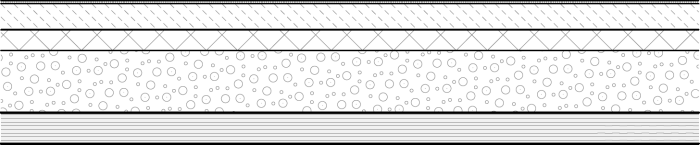

| Insulating board, e.g., Isover Akustic EP 1: | 40 mm |

| Bound gravel: | 120 mm |

| Board BauBuche: | 40 mm |

| Joists: | 120 / 320 mm |

| Gravel: | 16 / 32 mm |

| EPDM seal, single-layer laminated: | 1,55 mm |

| Tapered insulation EPS (20-240 mm): | 130 mm |

| Insulation PUR: | 120 mm |

| Vapour barrier/emergency seal: | 2 mm |

| BauBuche Board: | 40 mm |

| Joists: | 100 / 240 mm |

| 2x Plasterboard: | 2x 12,5 mm |

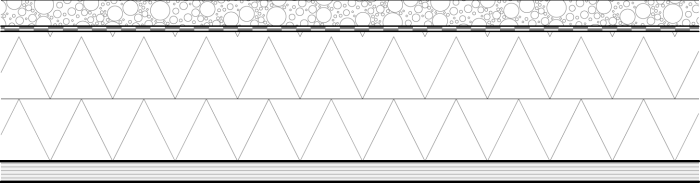

| Board OSB-3: | 15mm |

| Cellulose fibre insulation with timber posts 60/240 between: | 240 mm |

| Paraffin-treated soft wood fibre board: | 35 mm |

| Battens 30/60/ rear ventilation: | 30/60 mm |

| Timber formwork vertical, coated: | 21 mm |

| Heating: | District heating |

| Cooling: | Groundwater wells |

| Ventilation system: | With heat recovery |

Media is routed in the central zone of the building.

The streamlined BauBuche GL70 joists in the central zone with a cross-sectional height of just 160 mm leave enough space to route all the lines under the joists. Elaborate cutting of the joists is not necessary.

The great load-bearing capacity of the BauBuche GL70 Beams facilitates a particularly streamline design. This is demonstrated by material comparisons with conventional glued laminated timber GL24h.

| BauBuche GL70 | Glulam GL24h | |

| Columns | B x H = 200 x 200 | B x H = 240 x 240 |

| Joist 1st storey | B x H = 200 x 400 | B x H = 200 x 550 |

| Joist 2nd storey | B x H = 200 x 280 | B x H = 240 x 450 |

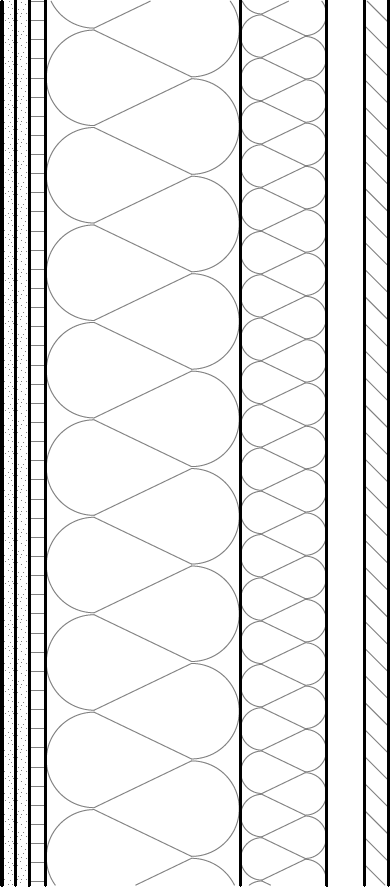

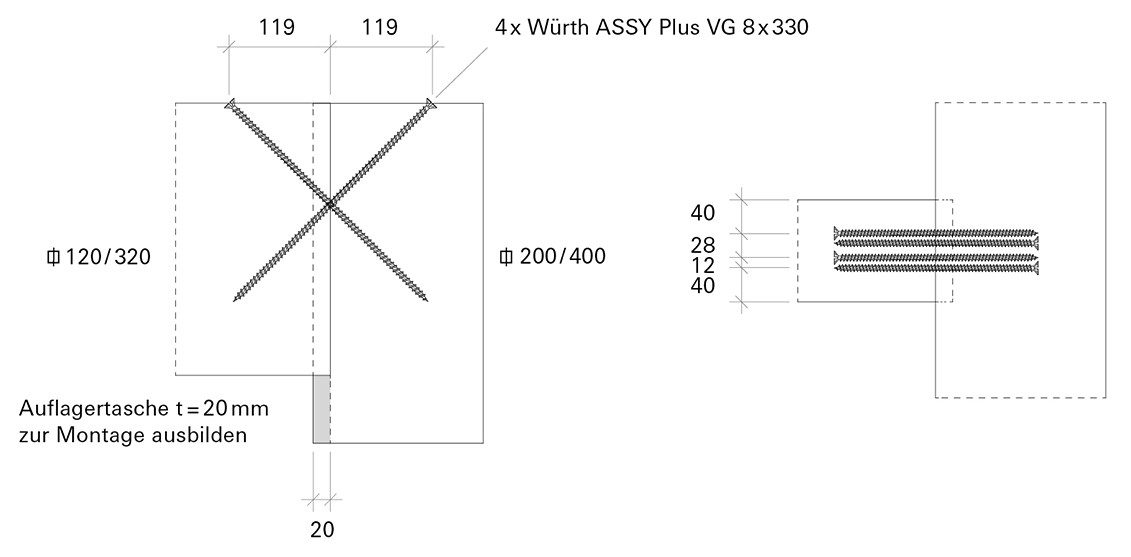

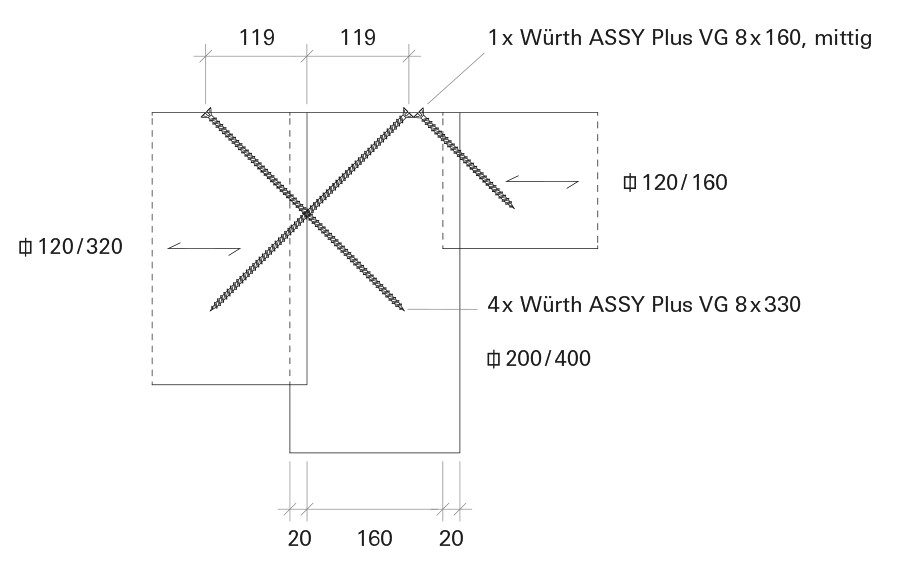

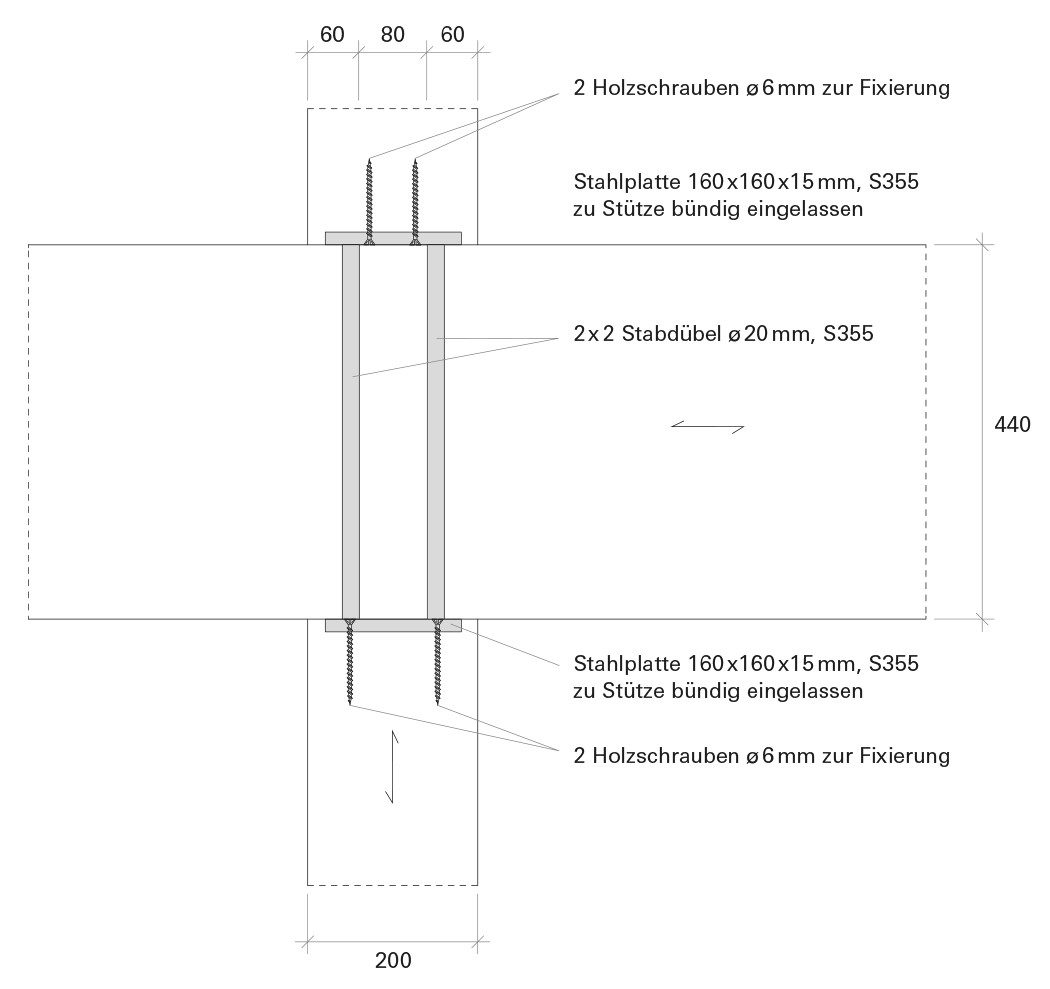

With the post and beam structure comparatively simple, flexible connections are used.

Right: Connection of a secondary beam.

Left: Connection of the smaller secondary beam in the central area.

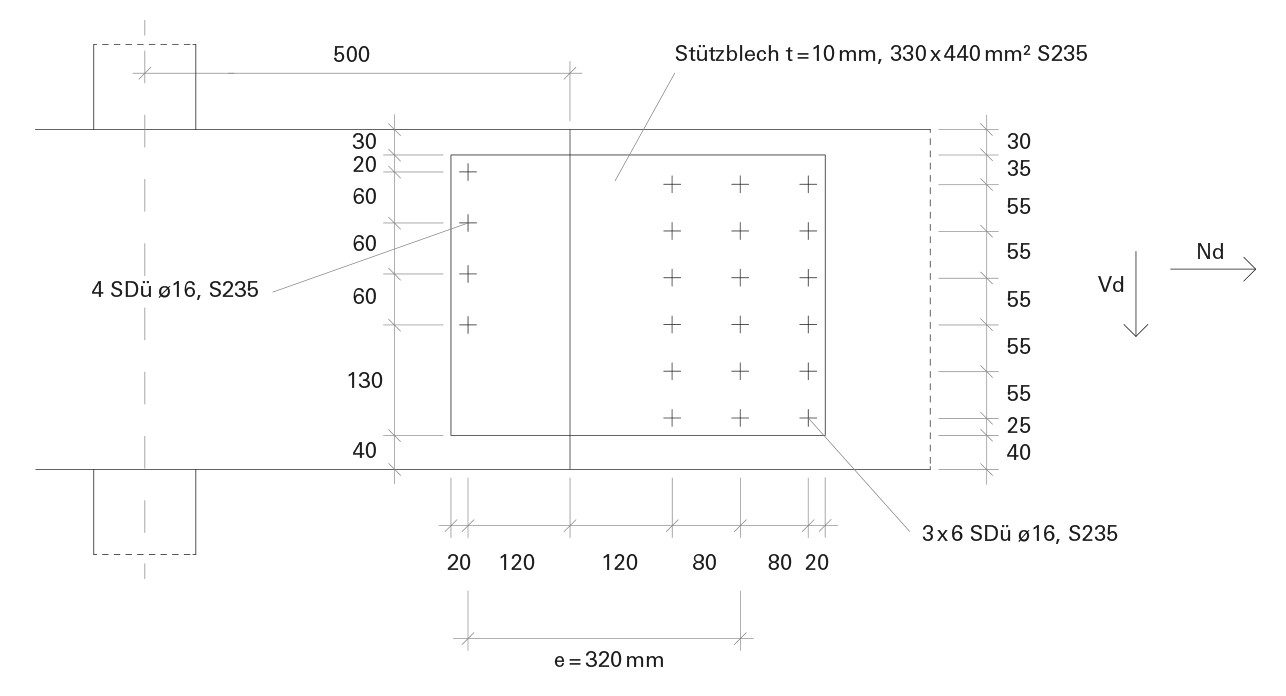

The high column forces are conducted through the joists via 4 dowels D = 20 mm of steel grade S355. The columns are secured in position through structural measures taken by the timber construction company.

How did your first timber construction project involving BauBuche go?

The Eurogen office building was the first project for which we used the new BauBuche material. When I took over management of the project, I was surprised by the small cross sections of the columns and beams. And I am still fascinated by just how streamlined constructions with BauBuche are. This is what makes BauBuche so special in my opinion. Processing and assembly were not without their complications. We had to go through an in-house learning process. Nevertheless, we would certainly use BauBuche again. And I am already looking forward to the next project.

What was your experience of trimming BauBuche?

After we received delivery of the first beams, I was of course struck by the high deadweight. The density of BauBuche is around 800 kg/m3 and the material boasts a corresponding strength. We trimmed the beams on our Hundegger K2. To keep the cutters on course, we had to set the speed of the joinery machine to the lowest track speed. This worked well.

Since all the screw holes for BauBuche had to be predrilled, there was a lot of drilling to be done. How was this?

We essentially made the drill holes with a diameter of 6 mm by hand. Spiral drills were great for this. Given the great hardness of BauBuche, the drills became very hot quickly. That’s why the colleagues always worked with numerous drills. After each drilled hole, the machine was changed to allow the drill to cool down. As an alternative, the drills can also be cooled down in an oil bath. I would not, however, recommend this since the oil drops can quickly soil the wood. Compared to softwood, significantly greater drill wear must be anticipated.

Recommendation from Pollmeier: When drilling in BauBuche, fully ground drills ensure the best results; e.g., FAMAG wood drill HSS-G long.

BauBuche is extremely sensitive to moisture. How did you cope with this?

That’s true. Moisture sensitivity is the central issue when assembling BauBuche. We produced the pockets in the main beams with an excess width of 2 mm so that the secondary beams would fit into them easily even if they have swelled slightly. Furthermore, all the columns and beams were given a moisture protection coating (BauBuche varnish from Koch und Schulte GmbH & Co.KG). When applying the BauBuche varnish, particular attention should be paid to the end faces. The beams were carefully stacked with laminated wood and wrapped in foil to ensure moisture protection during transportation and at the building site.

Recommendation from Pollmeier: BauBuche varnish is highly recommended as a protective coating for transportation and assembly. The layer thickness to be applied is 120 ml/m², that is the equivalent of one coat. Particular attention should be paid to the end grain areas – the end faces of the beams: Here we recommend 2 to 3 coats of BauBuche varnish. This is particularly important in the case of columns since the horizontal end faces can be subjected to rough weathering conditions.

How did assembly go?

Despite the many days of rain, assembly of the beams and columns went well. The protective coating more than proved its worth. Despite the varnish we still covered the structure in tarpaulins whenever it rained. The ceiling boards BauBuche Q, on the other hand, were cut to size and delivered untreated directly to the site by the manufacturer Pollmeier. Moisture protection proved more difficult here: We constructed a temporary, rain-proof storage box for the boards on site. The boards were only assembled on rain-free days and, immediately after they were laid, bitumen foil (BauderTEC KSD Duo) was applied to provide protection from the elements.

Were there still water marks on the boards?

Yes, despite our best efforts, there were still a few water marks. These can be removed with oxalic acid, which we did successfully.

Geschäftsführer der Holzbau Amann GmbH

Advice for architects, building engineers, clients and timber construction companies